What happens in the kitchen of a conveyor belt sushi restaurant? Let’s find out at Sushiro!

The mega popular kaitenzushi chain has a new branch in downtown Tokyo, and they let us into the back room.

Sushiro is one of Japan’s favorite kaitenzushi (conveyor belt sushi) chains, but many of their restaurants are located in the suburbs. So imagine our joy when a new branch recently opened up in Tokyo’s downtown Shinjuku Sanchome neighborhood, just a short walk from SoraNews24 headquarters!

It wasn’t long until our Japanese-language reporter Seiji Nakazawa dashed out the door to check the place out for himself. Rather than taking a seat in the dining area, though, on this day Sushiro was letting him into the back room for a close-up look at how they make their palate-pleasing, wallet-friendly sushi.

But before Seiji was allowed into the inner sanctum, he had some hygiene hurdles to clear. Anyone entering the kitchen is required to thoroughly wash their hands (following an eight-step process), change into an apron and hair net, remove any dust or debris from other exposed pieces of clothing, wash their hands once again, and put on a pair of gloves.

The procedure felt a little like he was purifying himself for some sort of religious ritual, and in a way he was, since for Sushiro, its kitchen is a sacred place.

Obviously, the use of technology is what separates conveyor belt sushi restaurants from regular sushi restaurants. Seiji quickly learned that the techno-culinary equipment doesn’t stop at mere conveyance, though. One of the first sights he saw inside the kitchen was a bank of multiple rice-cooking robots, since you can’t have sushi without rice.

And specifically, sushi requires vinegared rice, so once the rice-cooking robots are done cooking the grains, the human staff transfers it to the vinegar mixing machines.

There’s one more rice-prep step too, as after it’s had the vinegar added, the rice needs to be pressed into blocks (the verb for this in Japanese, nigiru, is where the term nigiri sushi, the most common kind of piece, comes from)

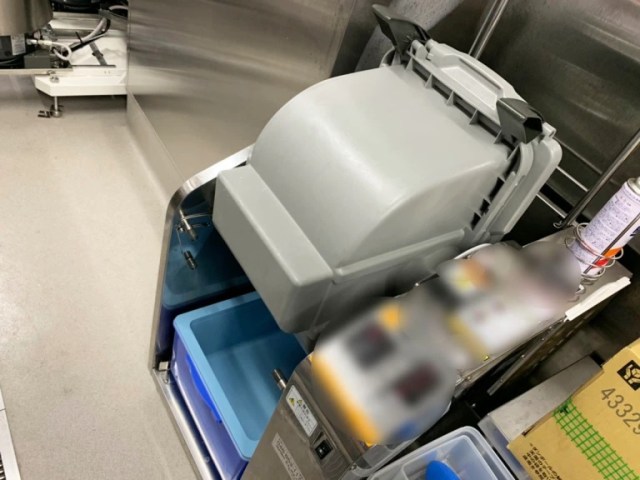

▼ One of Sushiro Shinjuku Sanchome’s four sushi rice-pressing machines.

The use of rice-pressing machines is sometimes a sticking point for sushi snobs, who insist that only a master chef’s hands can provide the proper results. Sushiro does take this classical ideal into account, though. Its rice-pressing machines are equipped with a low-level heater in order to replicate the warmth of human hands. They’re also configured to press the rice firmly enough so that the block doesn’t fall apart, but not so strongly that it becomes mechanically dense, and allowing for air to still travel between individual grains.

▼ The rice-pressing machine in action

There’s even a technological assist on the supply management side of things. Inside the kitchen is a monitor that displays and records what kinds of sushi customers are choosing and what times they’re eating it at. Analyzing this data allows Sushiro to predict not only what kind of fish is in demand, but when demand for it is going to spike, and this lets them put fresh pieces out on the conveyor right when they know people are going to be craving it.

▼ It’s basically the sushi version of Psycho-Pass or Minority Report

But as Seiji looked at all the ways technology was streamlining the sushi prep process, he couldn’t help but wonder about the rice. As mentioned above, there are three different machines involved in making a block of sushi rice, with a human employee transferring the rice between them each time. Why not just make the whole process automated in one do-everything contraption?

He decided to ask Sushiro Shinjuku Sanchome’s manager, Mr. Nishimori.

▼ Mr. Nishimori, fresh-slicing a cut of hamachi

The reason, he explained, is to maintain quality. Theoretically, you probably could build a machine where you just dump in raw rice, let it do its thing, and wait for it to spit out blocks of vinegared sushi rice. However, with sushi being one of the signature foodstuffs of Japanese cuisine, people’s standards are understandably high, and a human being looking at the rice at each intermediary stage, confirming whether or not it’ll meet diners’ expectations, is something they don’t want to pass off to an automated system.

▼ Seiji’s video report

So while you can’t have a conveyor belt sushi restaurant without technology, you can’t have one without people either.

Photos © SoraNews24

● Want to hear about SoraNews24’s latest articles as soon as they’re published? Follow us on Facebook and Twitter!

Credit:

0 comments:

Post a Comment