We travel to Fuji to see how they make Japanese toilet paper

From recycled paper to plush multi-ply, and guess what? There’s a smartphone game for you to try too!

Fuji City, located at the foot of Mt Fuji in Shizuoka Prefecture, is blessed with abundant water resources from the mountain, leading the area to become one of the largest “recycled paper producing areas” in the country, earning it the nickname “paper town“.

Our reporter Masanuki Sunakoma had been curious about Fuji’s paper-producing factories for years, and this week he was finally given the chance to infiltrate the premises of Corelex Shinei, a factory that’s said to be one of the “pioneers of coreless toilet paper rolls” in Fuji City.

He’d heard that the factory is capable of producing 1.3 million rolls of toilet paper a day, an amount his mind finds impossible to fathom, so when he arrived at the factory, he wasted no time in getting inside to see what it was all about.

Corelex Shinei isn’t just any old toilet paper factory — they focus on making high-quality products that don’t place an excessive burden on the environment. In particular, they specialise in recycling “miscellaneous waste” — paper waste that’s considered to be non-recyclable, but they have the magic required to recycle it into the highest quality paper products.

In other words, difficult-to-recycle paper products such as cup noodle lids, tickets, and paper with staples — all items that would usually be incinerated — are saved from becoming fumes that destroy the environment, and are given a new life as toilet paper instead.

▼ All this waste has been saved from the incinerator pile, and will eventually wind up in people’s bathrooms.

▼ For a sense of scale, this pile alone is over two Masanukis high.

These waste paper products, which have been collected from various local governments and companies, are packed into “tight bundles” before being transported into the factory via a large conveyor belt.

▼ This is the start of the long and winding journey to your bathroom.

First off, the raw materials are loosened a little with a sprinkling of warm water, which contains some chemicals to help break it all down.

The cardboard is left just as it is, and even if metal and plastics are mixed in with the paper here, it’s nothing that the factory can’t handle.

Everything then passes through to a machine called an “Ageing Tower”, where it’s left to sit for about 12 hours. This step makes it easier to separate the paper from other random things that may have been mixed in with it.

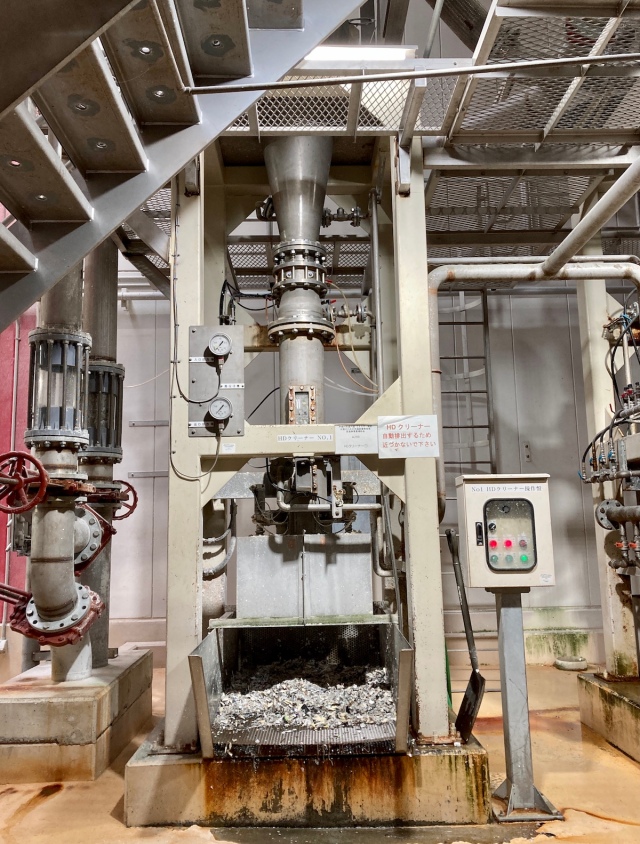

Then, centrifugal force is used to remove metals and hard objects like binder fasteners, while plastics float out of the mix and inks are removed at the same time.

After washing off the dirt, sterilizing and bleaching, the company’s managing director, Hitoshi Sano, told Masanuki to head over to the jumbo roll. This is the “giant toilet paper” storage area, where the paper sits before it becomes toilet paper.

▼ It’s hard to imagine that all this is essentially rolls and rolls of toilet paper.

▼ Like being in a giant’s bathroom.

Each roll is about three metres wide and 2.5 meters in diameter before it goes to the cutting area, where it’s cut into long, slender rolls.

Then, the rolls are finally cut into the regular-sized toilet roll shapes we’re all familiar with.

The newly made rolls then go through a security check area, where any defects are removed.

Those that are cleared safely are finally packed into bags in a process that’s mesmerising to look at.

Then, once the rolls are packed into boxes, a robot does the work of stacking the boxes up on top of each other.

The pallets are then taken to the truck with a forklift…

▼ The load is manually loaded without any gaps.

Watching this seamless production line made Masanuki feel as if he was watching a movie. The collected chunks of used paper were splendidly regenerated into toilet paper and he was impressed.

▼ That’s a serious supply of toilet paper.

▼ Masanuki felt as if he were the king of a toilet paper kingdom!

At the end of the factory tour, the staff told him about another sight that would blow his mind: a lifetime of toilet paper rolls. According to the person in charge, assuming a woman who uses more than a man, the average usage at one time seems to be 15.5 metres (in the case of double), and it is calculated to be about 5,657.5 meters in one year……

And 94.29 rolls a year is required for “1 roll 60 meters” of toilet paper. The average lifespan of a male is 81.64 years, women is 87.45, 84.43 and …… When you average it out, it workd out to be…

▼ This many toilet rolls!

▼ Yes, THIS many!

Seeing a lifetime of toilet paper all stacked together made Masanuki feel small, and yet he couldn’t resist the urge to give the giant stack a hug of gratitude for its great work.

Immediately after seeing the kingdom of toilet paper in the warehouse, he didn’t think it was overwhelming, but he was overwhelmed when a lifetime of toilet paper was stacked up in front of him.

▼ “Have I already used up half of you? I’ll continue to use you every day!”

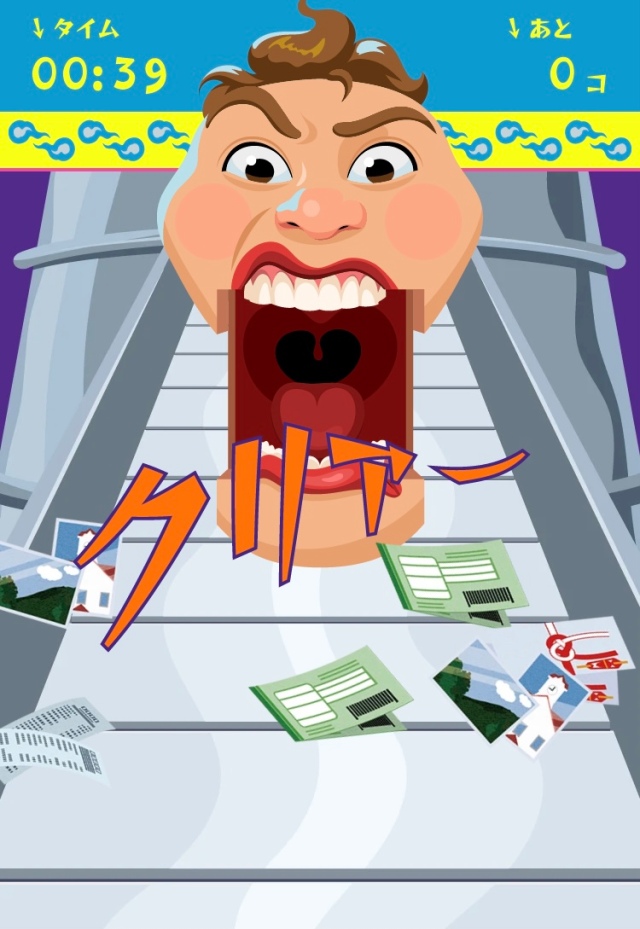

If you’d like to feel what it’s like to be the king of a toilet paper kingdom, you too can visit the factory, thanks to a virtual factory tour set up by the company. This is no ordinary virtual tour, though, as it walks you through the process of making toilet paper with the help of some clever gameplay.

playing games. And as mentioned earlier, the ” Infinite Toilet Paper Challenge 2021 “, where you can win a lifetime of toilet paper, has just started for a limited time!

If you take the virtual factory tour on a smartphone, you’ll be able to play a number of fun mini games, which involve clearing sections of the factory…

And testing your scrolling skills with the “Infinite Toilet Paper Challenge 2021”.

This game has an infinite amount of toilet paper to pull/scroll, and despite returning from the tour a few days ago, Masanuki is addicted to it.

It’s a fun way to learn more about the way toilet paper is made, and gives you a new appreciation for the things you take for granted in life, like the satisfaction of using a good toilet roll.

Now Masanuki is keen to visit the land of luxury loo rolls made by suppliers to the Imperial Family, which have sold out for 34 months running.

Related: Hayashi Kogyo Co., Ltd.

Photos: ©SoraNews24

● Want to hear about SoraNews24’s latest articles as soon as they’re published? Follow us on Facebook and Twitter!

Credit:

0 comments: